Reports: G7

47507-G7 Diffusion of structured polymers in confined environments

The central theme of this project is to explore the fundamental properties of dendrimers, which may eventually lead to dramatic improvement in the implementation for petroleum industry. For instance, dendrimers can work as additives to oil (e.g., dendrimer-coldflow-improver additive for depressing the pour point of oil in cold temperatures). On the other hand, aqueous polymer solutions are often used to sweep oil out of natural porous media in oil recovery. Nevertheless, little is known about the complex interaction between these structured molecules and the substrates. This interaction is critical for applying dendrimers in real world applications and is the focus of this project.

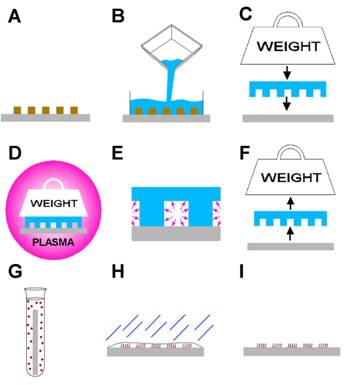

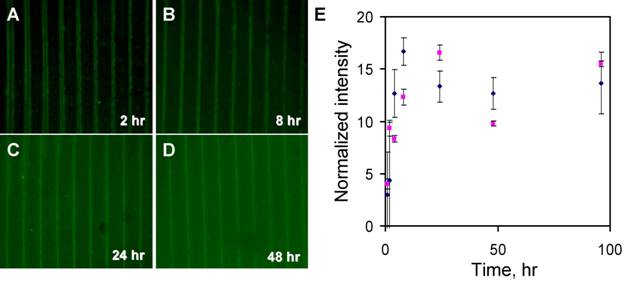

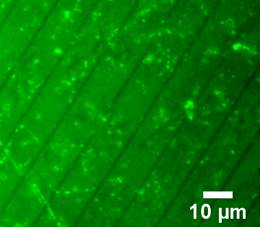

In this funding period, we have been able to successfully tag and pattern generation 7 Polyamidoamine (PAMAM) dendrimers having amino surface groups on plasma modified polymeric substrates, in particular polystyrene. Briefly, the dendrimers were tagged with fluorescein isothiocyanate (FITC) and dissolved in deionized water or phosphate buffer (PBS) solutions in order to carry out patterning. The tagging was accomplished by incubating acetone dissolved FITC with the dendrimers for 24 hours. Acetone was then removed by sparging the solution in air in order to have the acetone evaporate. This solution was then dialyzed for 24 hours with three changes of water to remove unbound FITC with a membrane selected to let the lighter molecular weight FITC diffuse to the surrounding water while retaining the tagged dendrimers. The dendrimers could then be patterned, which consisted of spatially arraigning them on a surface in a controllable manner. The patterning was possible at scales ranging from micrometers to centimeters and it is believed feasible to produce patterns in the nanometer size range. The patterning utilized a technique we have developed that can pattern polymeric and other types of surfaces by spatially controlling the contact of plasma to a surface (Figure 1). The selective contact is accomplished by using a three dimensional micro- or nanoscale mold that selectively shields the surface and provides channels in which plasma can flow and react with the surface. The result of this is that a chemical surface template is produced which can guide the adhesion of molecules. In the case of the dendrimers, we used air plasma to introduce negative surface functional groups to a polystyrene surface, which establish molecular level control of the dendrimer-surface interactions. This altered surface is able to capture the positively charged dendrimers and attach them in a noncovalent manner to the substrate (Figure 2).

We have also tested similar experimental procedures to other structural polymers/molecules including polyelectrolytes and biopolymers in order to compare the dendrimer result and extract the essential characteristics of the polymer-surface interactions. Optimization procedures were performed across a variety of soak durations and pH levels and tests were performed to determine ionic strength and adhesion characteristics. Soak durations were performed on all the molecules. Durations were performed at 1, 2, 4, and 8 hours, as well as 1, 2, and 4 days. Longer durations were deemed unnecessary and redundant. In short duration, the deposition kinetics is roughly proportional to t1/2, which indicates the initial kinetics is dominated by molecular diffusion of the polymer (Figure 3). While the assembly can be observed as short as 1 hour, we found the absorption is weak and incomplete, as indicated by the random distribution of the absorption molecules and low yield of the process. The varying pH levels were performed on both molecules and on the FITC control group. A series of 6 samples were taken, varying linearly between approximate pH levels of 3.5 and 9. After observations were made, lower and higher pH levels were determined to be unnecessary. Once the optimum pH level was attained, this was used for the remainder of experimentation. Tests were performed on both protein samples to determine their respective ionic strength characteristics and to better understand their respective adhesion characteristics. These tests were likewise carried out on the FITC control group. All observations and analysis was done visually using photographs attained from the microscope. Analyses of the photographs were done to prepare more directly comparable results.The dendrimer arraignment can then be detected with a fluorescence microscope due to the presence of the attached FITC dye. To eliminate the possibility that the observation is a result of the FITC label instead of the dendrimer, we have performed the experiment with FITC individually. Our results indicate insignificant binding of the molecular to the plasma treated surfaces.

Current work is focusing on optimizing the solution conditions to control the amount and type of binding that the dendrimers have to the surface. Optimization is accomplished by adjusting the pH and ionic strength of the carrier solution as well as changing what substrate and gas are used in order to force different surface to particle interactions to occur. Additionally, work is being carried out to increase the resolution of the technique and characterization of the resulting surface-dendrimer interaction in order to be able to produce nanoscale dendrimer patterns and implement the scheme for other polymers.

Figure 1. Plasma lithography

procedure for probing dendrimer-surface interactions. (a) Photolithography defined master

structures created out of photoresist (tan).

(b) PDMS (blue) poured over master and cured. (c) Mold removed from master and placed on

substrate. Weight placed on mold to

ensure conformal contact with the substrate.

(d) Substrate-mold-weight assembly plasma treated. (e) Selective plasma treatment to exposed

areas. (f) Mold and weight removed after

plasma treatment. (g) Substrate placed

in dendrimer solution for self-assembly.

(h) and (i),

Substrate removed from solution then rinsed and dried revealing solute

assembled onto pattern.

Figure 2. Self-assemble of generation 7 PAMAM dendrimers on a polystyrene substrate.

Figure 3. Kinetics of the assembly process. (A-D) Observation of polymer adhesion of polymers with different incubation duration. (E) Normalized intensity as a function of time.