Reports: G7

47143-G7 The Effects of Polydispersity on the Melt-Phase and Aqueous Solution-Phase Behavior of ABA Triblock Copolymers

Overview. Comprised of chemically dissimilar homopolymer segments joined together into a single macromolecule, block copolymers microphase separate to form ordered nanoscale structures. Microphase separation results from the balance of enthalpically unfavorable interactions between the immiscible homopolymer blocks and the inherent entropic elasticity of the polymer chains. The phase behavior of AB diblock and ABA triblock copolymers having narrow molecular weight distributions is parameterized by the polymer composition or volume fraction fA = 1- fB, the overall degree of polymerization N, and the Flory-Huggins χABinteraction parameter that quantifies block immiscibility. Extensive theoretical predictions and complementary experimental studies have established the general phase behavior and topology of the monodisperse AB and ABA block copolymer phase diagrams in the absence of strong non-covalent interactions. These specialty polymeric materials are widely used as pressure sensitive adhesives, thermoplastic elastomers, and as macromolecular surfactants.

Advances in synthetic polymer chemistry have enabled the controlled synthesis of block copolymers derived from a variety of chemical feedstocks with control over the average polymer molecular weight and the shape and breadth of the molecular weight distributioncontrolled polydispersity. Recent studies of the implications of controlled block polydispersity on the self-assembly of block copolymers have focused primarily on AB diblock and ABA triblock copolymers having polydisperse A blocks. These materials self-assemble with relatively small differences in the experimentally observed equilibrium phase behavior as compared to their monodisperse counterparts. We have recently found that ABA triblock copolymers with polydisperse center B blocks self-assemble into a variety of structures, with important differences as compared to systems with polydisperse A end blocks. Our studies have focused on the weakly segregated ABA-type triblock copolymer model system poly(styrene-b-1,4-butadiene-b-styrene) (SBS).

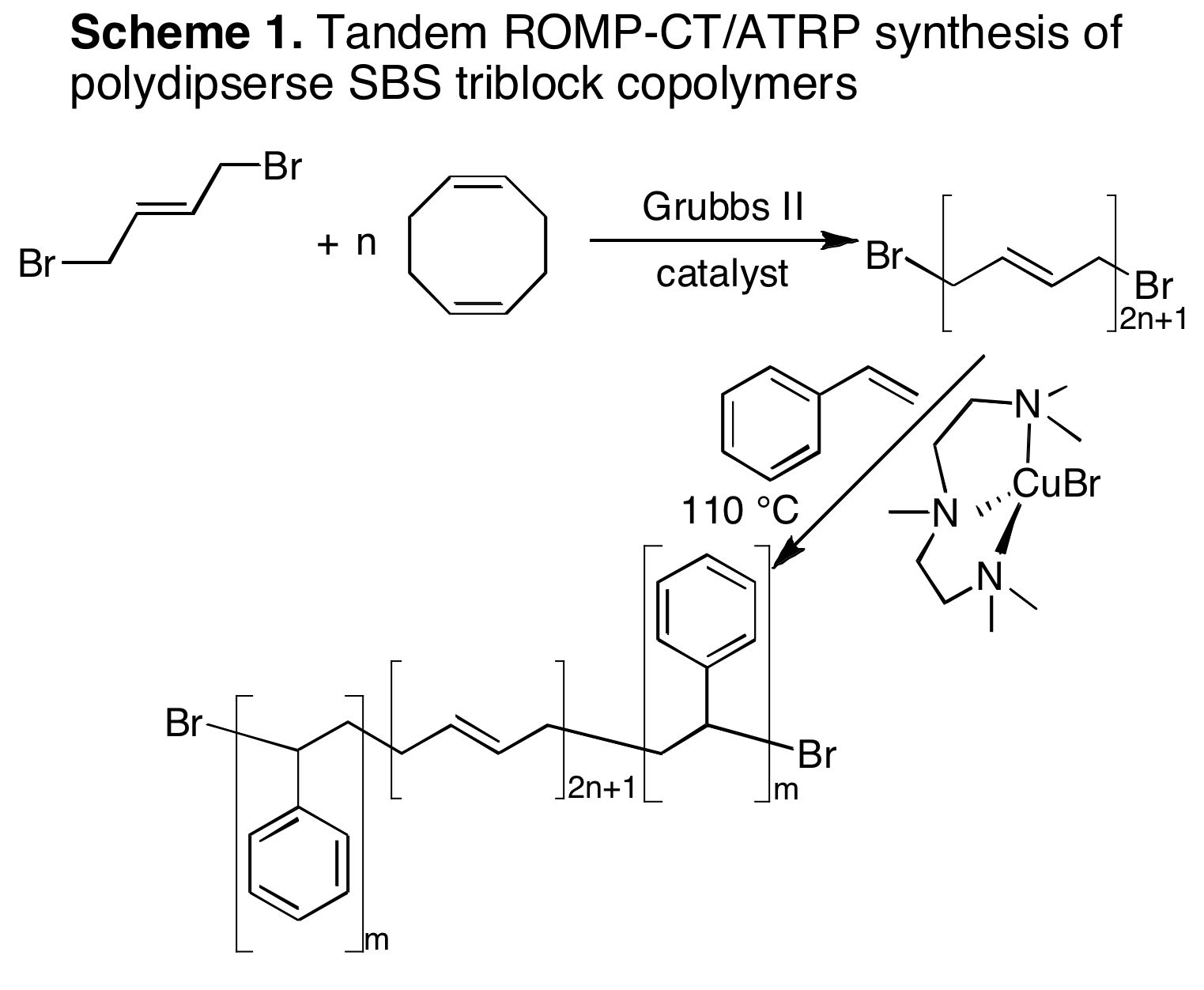

General Synthetic Strategy. Our synthetic strategy relies on chain transfer ring-opening metathesis polymerization (ROMP-CT) of 1,5-cyclooctadiene using Grubbs 2nd generation catalyst to produce α,ω-dibromo-poly(1,4-butadiene) with a polydispersity Mw/Mn = 2.0. Using tandem Cu-catalyzed atom transfer radical polymerization (ATRP), the allylic bromide termini are used to initiate the controlled polymerization of styrene (Mw/Mn ≤ 1.15 for each styrene block) to afford model SBS triblocks with polydisperse center segments. By this methodology, one graduate student and one undergraduate student supported by ACS PRF funding have produced a library of polymers having a range of compositions and molecular weights that have been characterized by a combination of 1H NMR and size exclusion chromatography (SEC).

metathesis polymerization (ROMP-CT) of 1,5-cyclooctadiene using Grubbs 2nd generation catalyst to produce α,ω-dibromo-poly(1,4-butadiene) with a polydispersity Mw/Mn = 2.0. Using tandem Cu-catalyzed atom transfer radical polymerization (ATRP), the allylic bromide termini are used to initiate the controlled polymerization of styrene (Mw/Mn ≤ 1.15 for each styrene block) to afford model SBS triblocks with polydisperse center segments. By this methodology, one graduate student and one undergraduate student supported by ACS PRF funding have produced a library of polymers having a range of compositions and molecular weights that have been characterized by a combination of 1H NMR and size exclusion chromatography (SEC).

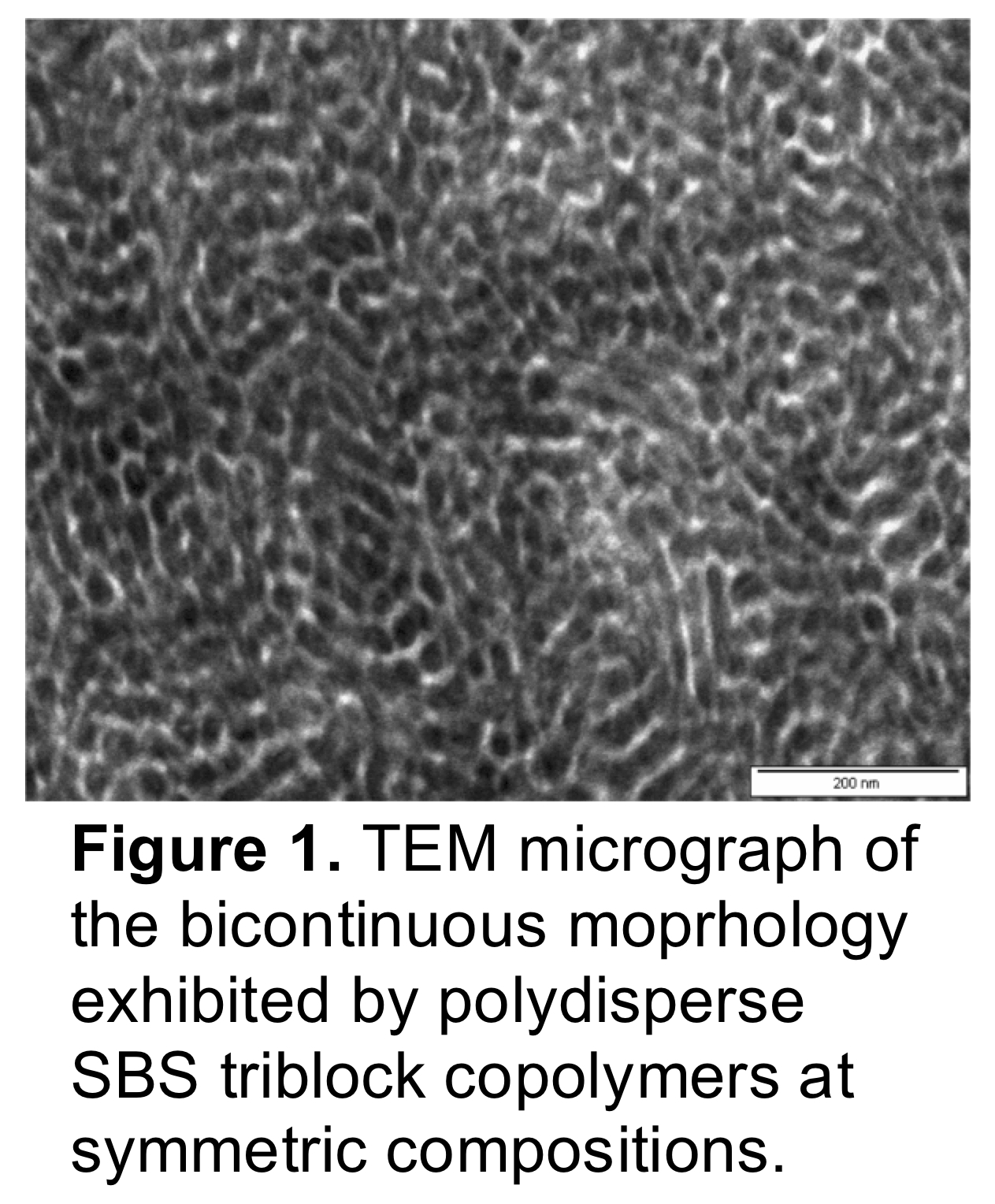

Melt-phase Behavior of Model SBS triblock copolymers. Polydisperse SBS triblock copolymers with melt segregation strengths χN ≤ 20 at 150 °C microphase separate into ordered structures having variable degrees of long-range order as evidenced by small-angle x-ray scattering (SAXS) and transmission electron microscopy (TEM). Depending on the polymer composition, polydispersity may frustrate ordering of the microphase separated polymer melt.  Temperature-dependent SAXS analyses of ordered melts at symmetric compositions (fstyrene = fbutadiene = 0.5) reveal large increases in the order-disorder transition temperatures, indicating tremendous stabilization of these microphase separated structures. TEM analysis of symmetric polydisperse SBS copolymers reveals that these materials adopt a bicontinuous structure upon thermal annealing, in contrast to their monodisperse counterparts that adopt lamellar phases. Solvent casting these samples followed by thermal annealing yields samples with well-ordered morphologies, some of which exhibit phase coexistence as evidenced by the appearance of broad principal scattering reflections by SAXS. Ongoing TEM analysis provides evidence for phase coexistence in these materials. Our work has established that the lamellar phase window for these polydisperse SBS materials is shifted much more dramatically as compared to diblock copolymers containing a single polydisperse block. This result exemplifies our general finding that the phase boundaries for polydisperse melts shift and the intermaterial dividing surfaces preferentially curve toward the polydisperse segment.

Temperature-dependent SAXS analyses of ordered melts at symmetric compositions (fstyrene = fbutadiene = 0.5) reveal large increases in the order-disorder transition temperatures, indicating tremendous stabilization of these microphase separated structures. TEM analysis of symmetric polydisperse SBS copolymers reveals that these materials adopt a bicontinuous structure upon thermal annealing, in contrast to their monodisperse counterparts that adopt lamellar phases. Solvent casting these samples followed by thermal annealing yields samples with well-ordered morphologies, some of which exhibit phase coexistence as evidenced by the appearance of broad principal scattering reflections by SAXS. Ongoing TEM analysis provides evidence for phase coexistence in these materials. Our work has established that the lamellar phase window for these polydisperse SBS materials is shifted much more dramatically as compared to diblock copolymers containing a single polydisperse block. This result exemplifies our general finding that the phase boundaries for polydisperse melts shift and the intermaterial dividing surfaces preferentially curve toward the polydisperse segment.

These melt-phase behavior studies of polydisperse block copolymers may have important implications for the synthesis of mechanically robust, nanostructured materials for applications ranging from pressure-sensitive adhesives to defect-free block copolymer processing to porous filtration and ion transporting membranes.